Summary of Contents for Honeywell PW6K1OUT

- Page 1 Pro-Watch 6000 Input Module PW6K1OUT Installation Guide July 14, 2008 © 2008 Honeywell. All rights reserved. 800-01953, Revision B...

- Page 2 All product and brand names are the service marks, trademarks, registered trademarks, or registered service marks of their respective owners. Printed in the United States of America. Honeywell reserves the right to change any information in this document at any time without prior notice.

-

Page 3: Table Of Contents

ONTENTS Front Matter Warnings and Cautions ..................v Disclaimer ......................vi Unpacking Procedure ..................vii Shipping Instructions ..................vii Limited Warranty ....................viii Confidentiality....................viii Installing the PW-6000 Output Module Description ......................1 Specification......................2 Set Up........................2 LED Operation ...................... 5 Power........................ - Page 4 www.honeywell.com...

-

Page 5: Front Matter

DO NOT ACCEPT VERBAL APPROVALS, BECAUSE THEY ARE NOT VALID. Honeywell never recommends using the PW-6000 or related products for use as a primary warning or monitoring system. Primary warning or monitoring systems should always meet local fire and safety code requirements. The installer must also test the system on a regular basis by instructing the end user in appropriate daily testing procedures. -

Page 6: Disclaimer

Customer harmless for any costs or damages including reasonable attorneys' fees which Customer may be required to pay as a result of the defective Product or the negligence of Honeywell, its agents, or its employees. -

Page 7: Unpacking Procedure

• If any other defect is apparent, call for a return authorization. Shipping Instructions To ship equipment back to Honeywell, Inc.: 1. Contact the customer service department at 800-232-4576 before returning equipment. When you call please have available: •... -

Page 8: Limited Warranty

All Products sold or licensed by Honeywell include a warranty registration card which must be completed and returned to Honeywell by or on behalf of the end user in order for Honeywell to provide warranty service, repair, credit or exchange. All warranty... -

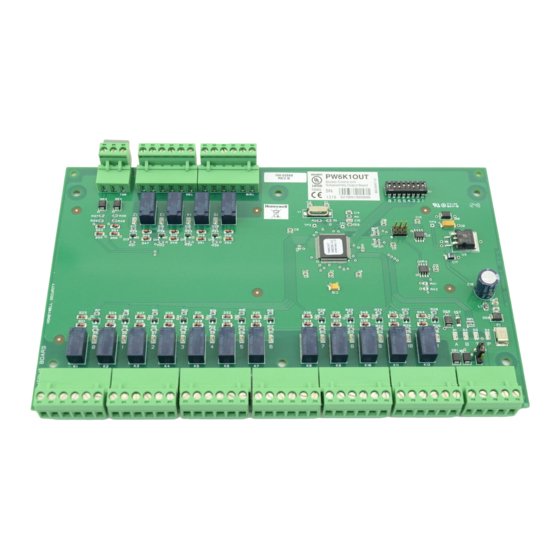

Page 9: Installing The Pw-6000 Output Module

Installing the PW-6000 Output Module Description The Output Board provides connections for 16 relay outputs. You can either mount the board in a rack or open and flat. If you rack-mount the board, only one edge is accessible for wiring; however, a flat mount increases the amount of available I/O slightly but significantly decreases the number of boards that can be mounted in one enclosure. -

Page 10: Specification

0°C to +49°C, operating, -55°C to +85°C, storage Humidity 0% to 85% RHNC Set Up Table 1: PW6000 Output Module Jumper Setting Jumper Setting Default Selected Port 1 RS-485 EOL terminator is not active Port 1 RS-485 EOL terminator is active www.honeywell.com... - Page 11 Installing the PW-6000 Output Module Set Up Table 2: PW6000 Output Module DIP Switch Settings Selection ADDRESS 0 ADDRESS 1* ADDRESS 2 ADDRESS 3 ADDRESS 4 ADDRESS 5 ADDRESS 6 ADDRESS 7 ADDRESS 8 ADDRESS 9 ADDRESS 10 ADDRESS 11 ADDRESS 12 ADDRESS 13 ADDRESS 14...

- Page 12 Table 2: PW6000 Output Module DIP Switch Settings (continued) Selection ADDRESS 23 ADDRESS 24 ADDRESS 25 ADDRESS 26 ADDRESS 27 ADDRESS 28 ADDRESS 29 ADDRESS 30 ADDRESS 31 Reserved 9,600 BPS 19,200 BPS 38,400 BPS* Not Used* * = Default www.honeywell.com...

-

Page 13: Led Operation

Installing the PW-6000 Output Module LED Operation LED Operation The Output Board uses two onboard LEDs to provide status information during the power-up sequence and during normal operation. Table 3: LED Settings Mode LED D1 LED D2 Description Power-up Start power-up, hardware setup sequence Testing RAM Testing ROM and completing... -

Page 14: Power

2. TR- is the negative side of the transmit and receive differential signal. 3. GND is the signal ground. The wiring for this signal is required and optional. This signal must be connected to chassis GND. 4. Use 24 AWG low capacitance, two twisted-pair, shielded cable (Belden 9842 or equiv.). www.honeywell.com... -

Page 15: Wiring

Installing the PW-6000 Output Module Wiring For RS-485 Communication Connections, twist the blue pair together Note: and use as the common; use the orange pair as your data pair, observing polarity. Connect the external drain shield to the appropriate earth ground on one end. -

Page 16: Mounting Options

Mounting Options This board can be mounted on-edge in the rack-mount enclosure provided by Honeywell, or it can be mounted flat against any surface using standoffs under the mounting holes provided in each of the four corners of this board. -

Page 17: Wiring Diagram For Connectors 1 Through 8

Installing the PW-6000 Output Module Wiring Diagram for Connectors 1 through 8 Wiring Diagram for Connectors 1 through 8 Figure 1: PW-6000 Output Module Wiring: Connectors 1-8 Short OUTPUT BOARD RELAY0 NO together* RELAY0 C RELAY0 NC RELAY1 NO RELAY1 C RELAY1 NC RELAY2 NO RELAY2 C... -

Page 18: Wiring Diagram For Connectors 7 Through 10

+ 12V For RS-485 Communication Connections, twist the blue pair together and use as the common; Note: use the orange pair as your data pair, observing polarity. Connect the external drain shield to the appropriate earth ground on one end. www.honeywell.com... - Page 19 Honeywell Integrated Security 135 W. Forest Hill Avenue Specifications subject to change Oak Creek, WI 53154 without notice. United States 800-323-4576 © Honeywell. All rights reserved. 414-766-1798 Fax www.honeywellintegrated.com Document 800-01953, Revision B...